Ultra II™ Series: High Efficiency "Low Nox"

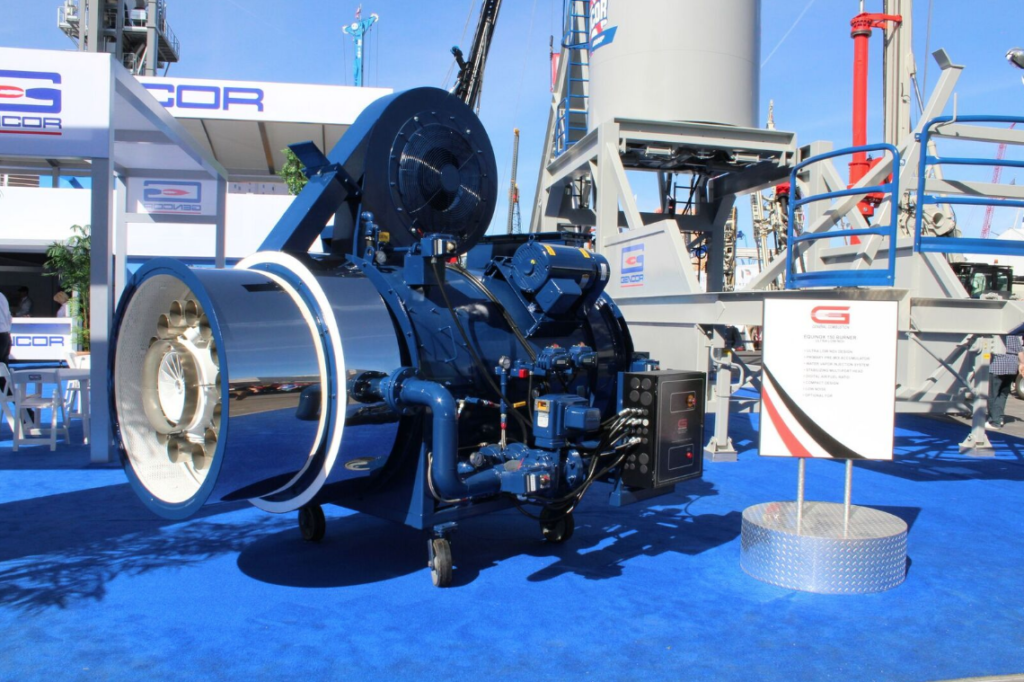

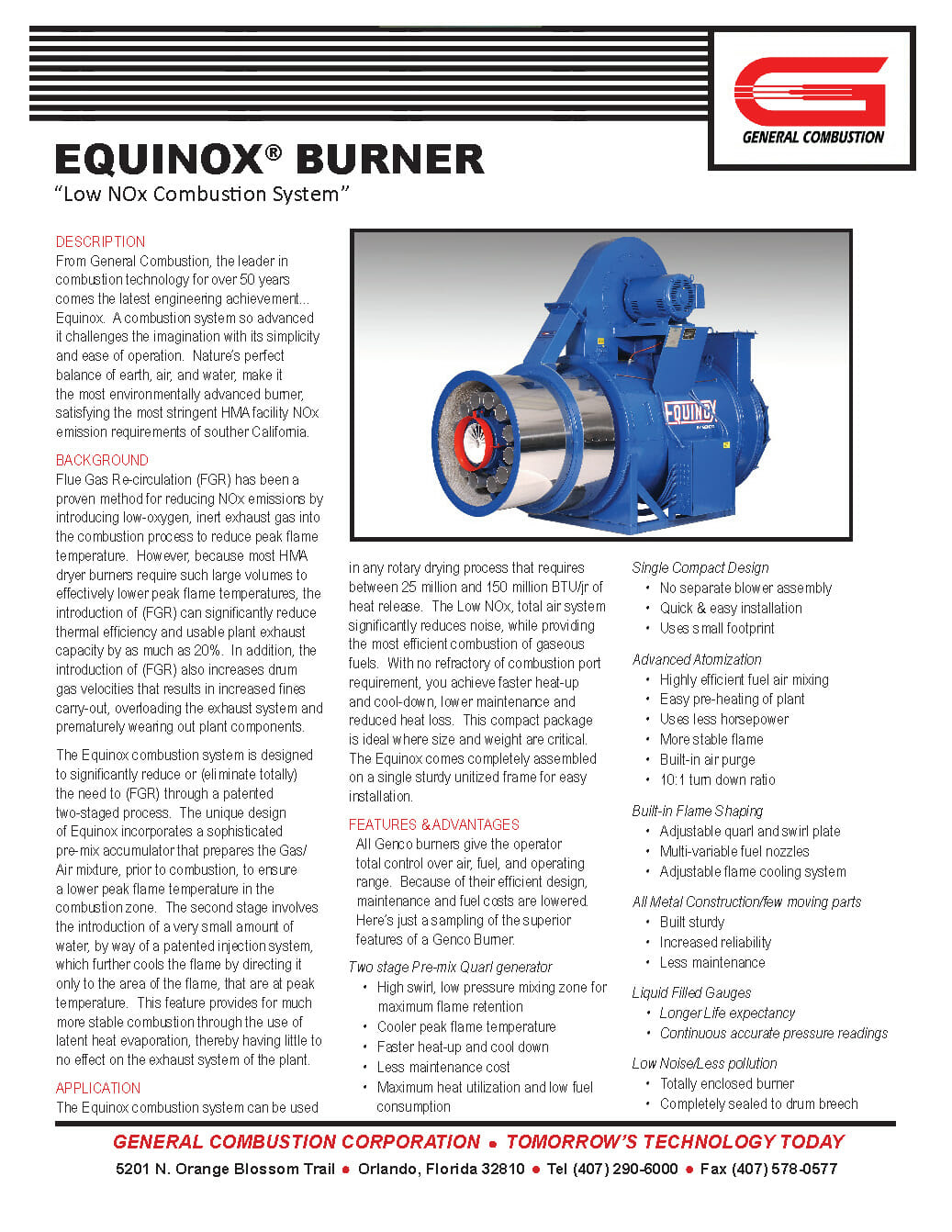

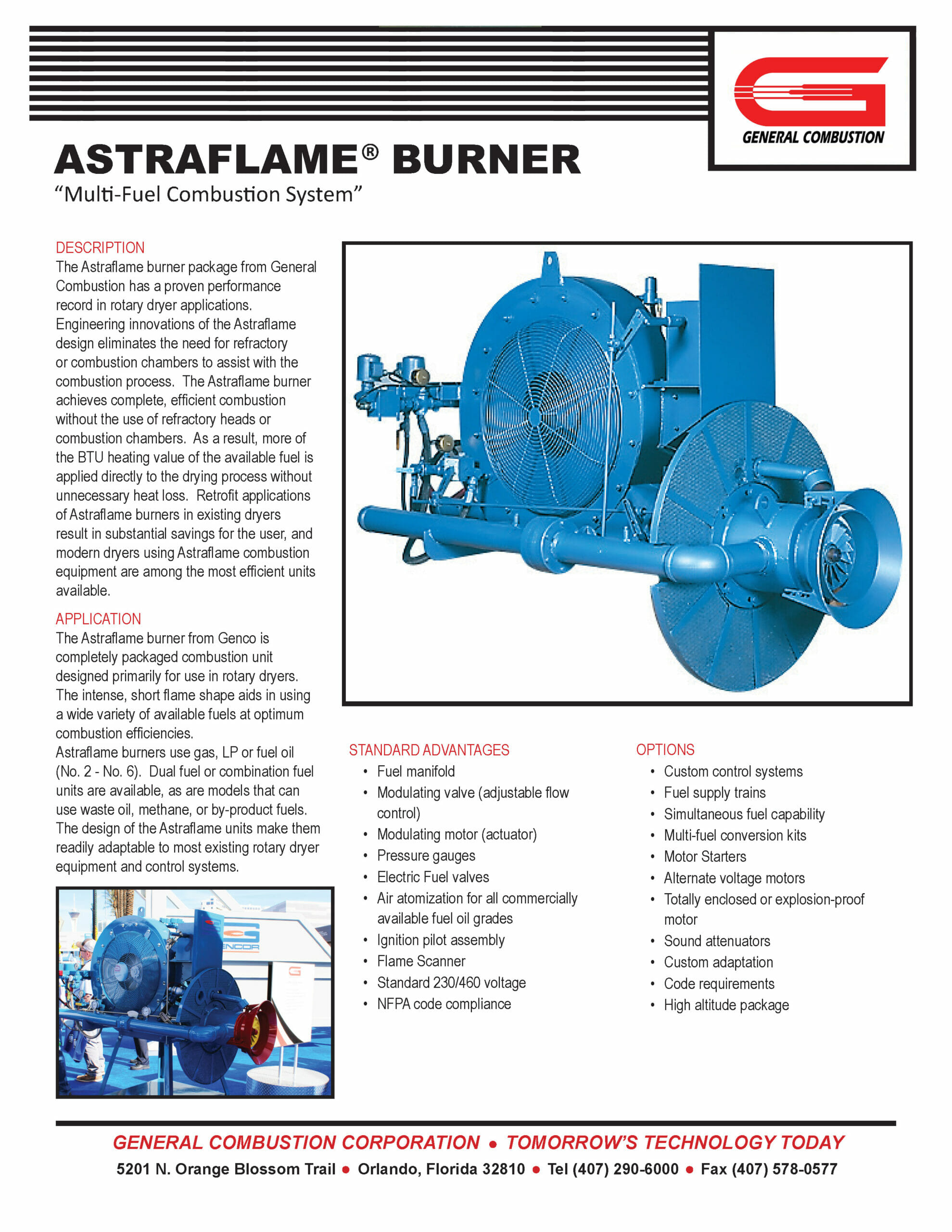

Genco’s ULTRA II™ burners can be used in any rotary drying process that requires between 25 million and 150 million BTU/hr of heat release.

The Low Nox, total air system significantly reduces noise while providing total and efficient combustion of conventional fuels-whether oil, gas, LP or Coal.

With no refractory or combustion port requirement, you achieve faster heat-up and cool-down, lower maintenance and reduced heat loss. This compact package is ideal where size and weight are critical.

The ULTRA II™ comes completely assembled on a single sturdy unitized frame for easy installation.