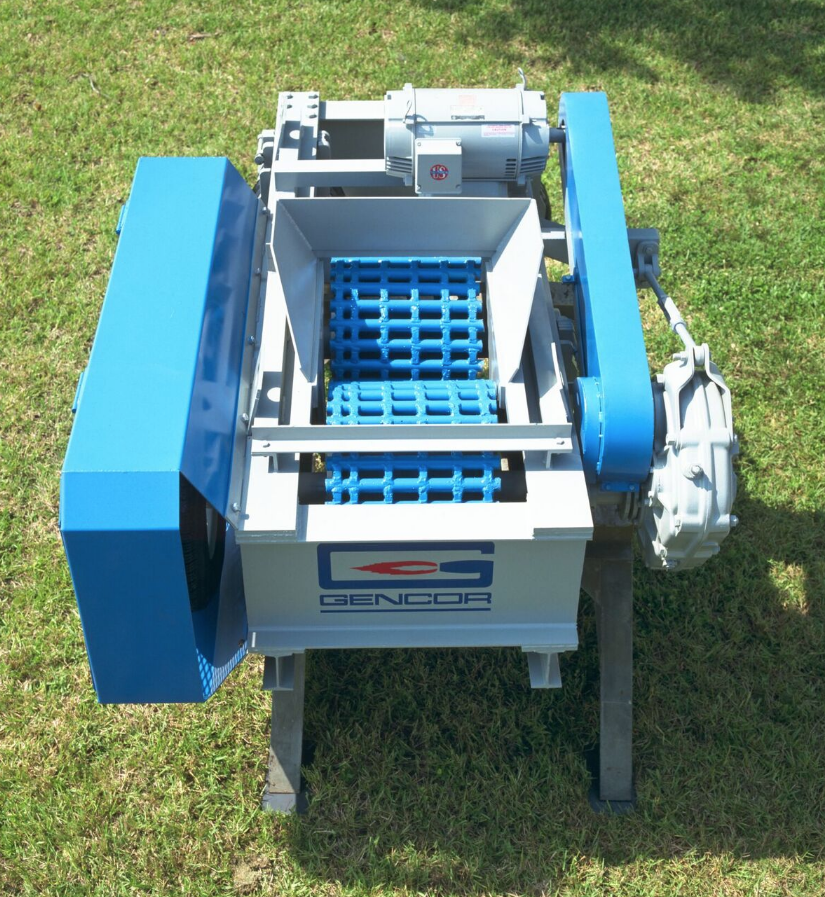

Giraffe Recycle System

The Gencor® Giraffe RAP unit combines a bin and feeder, lump breaker, vibrating screen, and scale conveyor into a single easily transportable unit. The Giraffe’s unique bin design eliminates material bridging, with steep-sided tapered walls, self-relieving throat and welded beater plates on the sides of the bins. The rack and pinion adjustments allow the bin gates to be easily raised or lowered to maintain the correct amount of RAP being fed for precise material flow. The Gencor® exclusive double-drum RAP lump breaker can easily reduce RAP material size without crushing the aggregate and is designed with a unique self-relieving tire and air bladder drive system. A long, folding, reversible bulkhead can accommodate any plant arrangement and provides for bin loading from either side for optimum versatility on varying job sites. All Gencor® Giraffes come completed with quick disconnect cabling, disc wheels and, two-speed landing gear to reduce the cost of setup and transport.

Features:

- Self-relieving 8 x 14 steep-sided bin

- 4 x 12 Inclined scalping screen

- Precision Weigh Bridge ensures accurate material weighing

- 18-ton struck capacity

- Dual no-flow sensors

- Variable Direct speed drive system

- ¼: sidewall construction

- Optional magnet