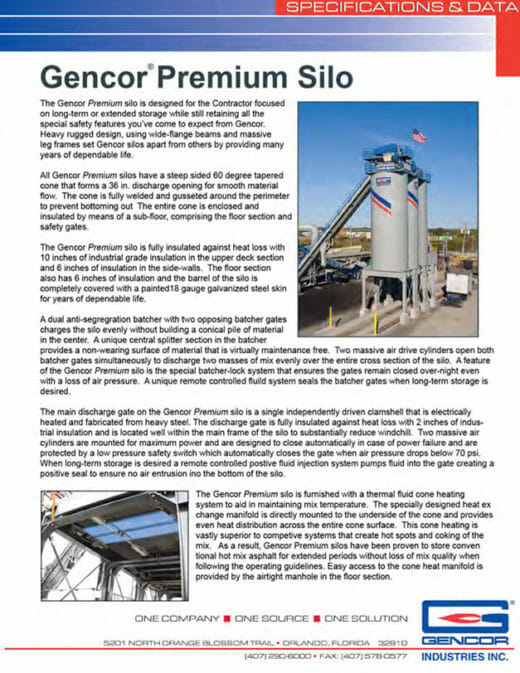

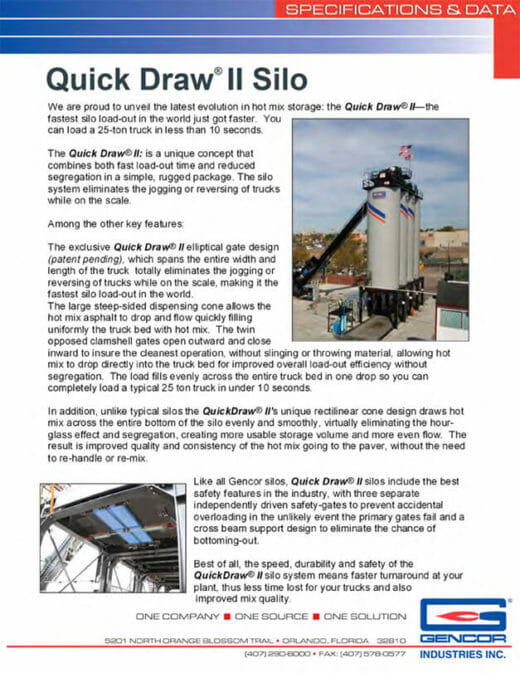

Deluxe Silo

Innovative design and quality construction have maintained the reputation of Gencor hot mix storage systems around the world. The continuous-weld silo body provides enormous strength and maximum structural integrity to tolerate heat and vibration. The unique cone support design eliminates the risk of bottoming out. Gencor unique design features, such as the dual-flow batcher and dual safety gates, make Gencor the most dependable and safest silo storage system in the industry.

The safety gate system is independently driven and wired to prevent accidental overloading and provides a second lock against air intrusion while reducing truck and scale clean-up. A totally enclosed cone provides a protective skirt for maximum heat retention.

The massive seismic frame construction is unmatched in the industry; typically 20-30% heavier to withstand vibration and movement.

Features:

- Heavy Duty I-beam support legs

- ¼” double welded body

- Dual-flow anti-segregation batcher for even distribution

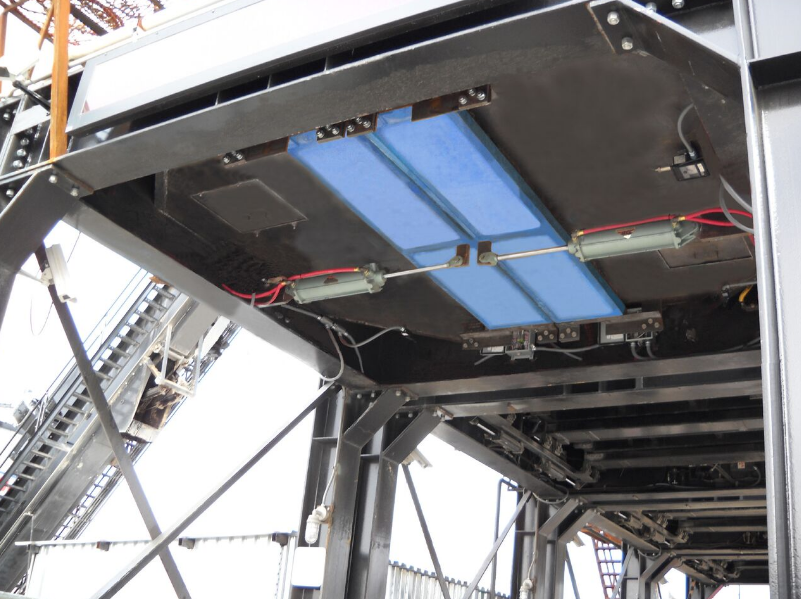

- Industrial board insulation eliminates sagging

- Dual safety gates

- Oil or floating electric cone heat

- Material level indicators

- Thermotite seals (optional)

- Patented blue smoke system (optional)

- Portapads (optional)