HY Series

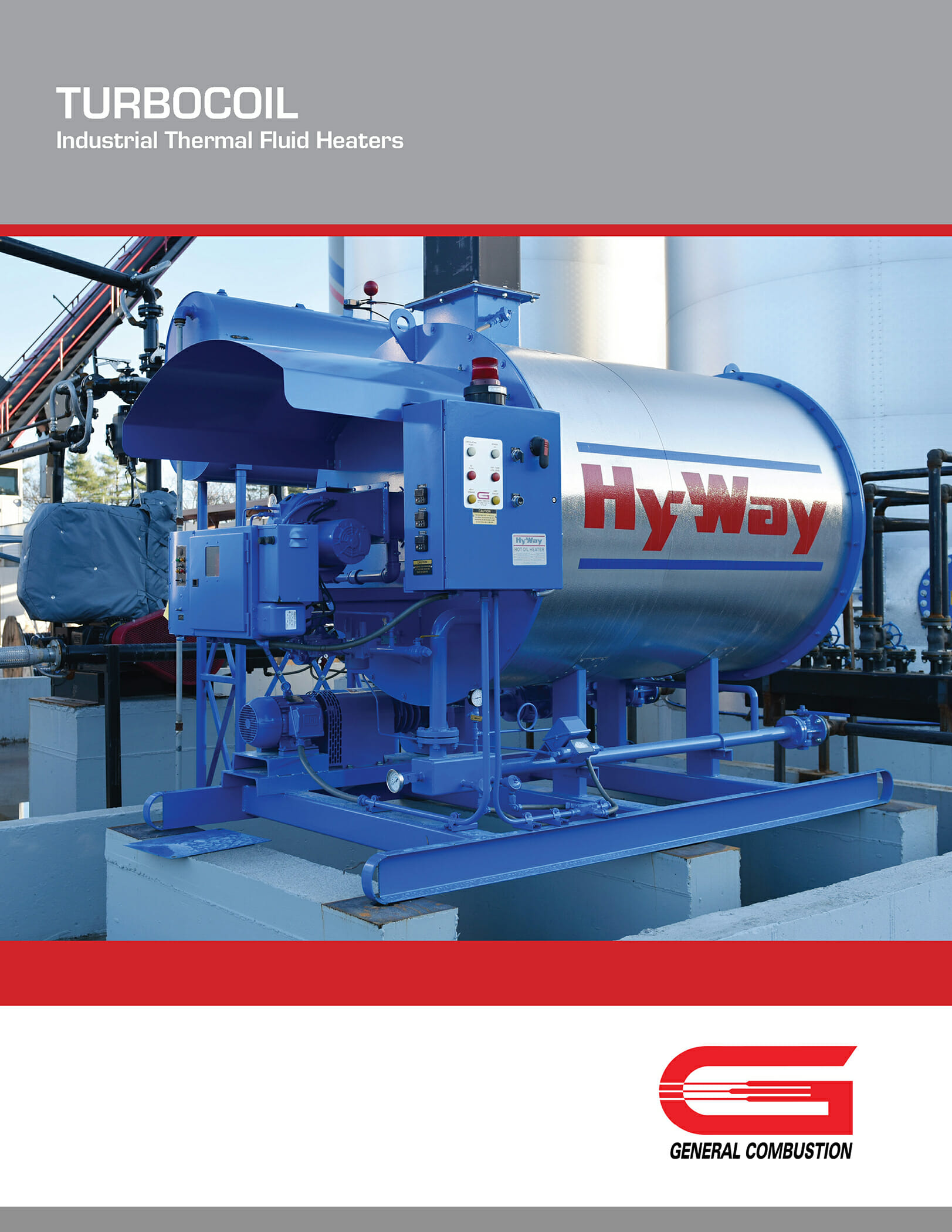

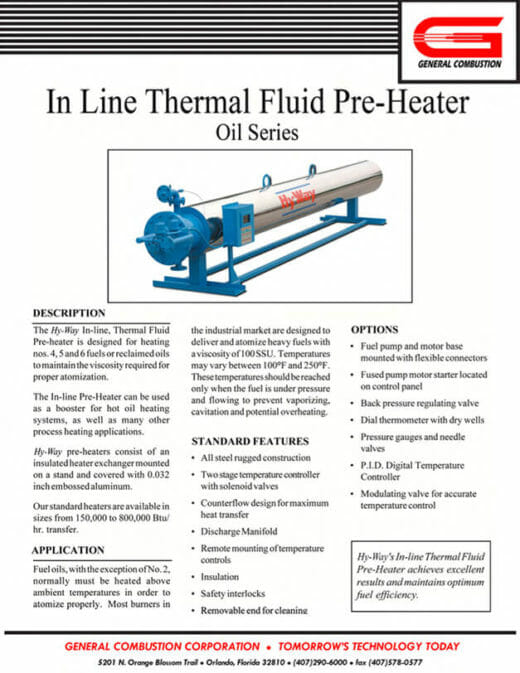

The industry’s best choice for low-cost and efficient thermal fluid heat is the HY Series.

HY heaters incorporate the basic, sound design features of Hy-Way’s® other well-established models, including a helical coil design for maximum efficiency, high flow centrifugal pump, multi fuel burner, external insulation and low stack temperatures in an economical package.

Skid-mounted for easy installation, HY heaters are suitable for either indoor or outdoor application. HY heaters are capable of utilizing Natural Gas, LP Gas, No.2 fuel oil or combination fuels.