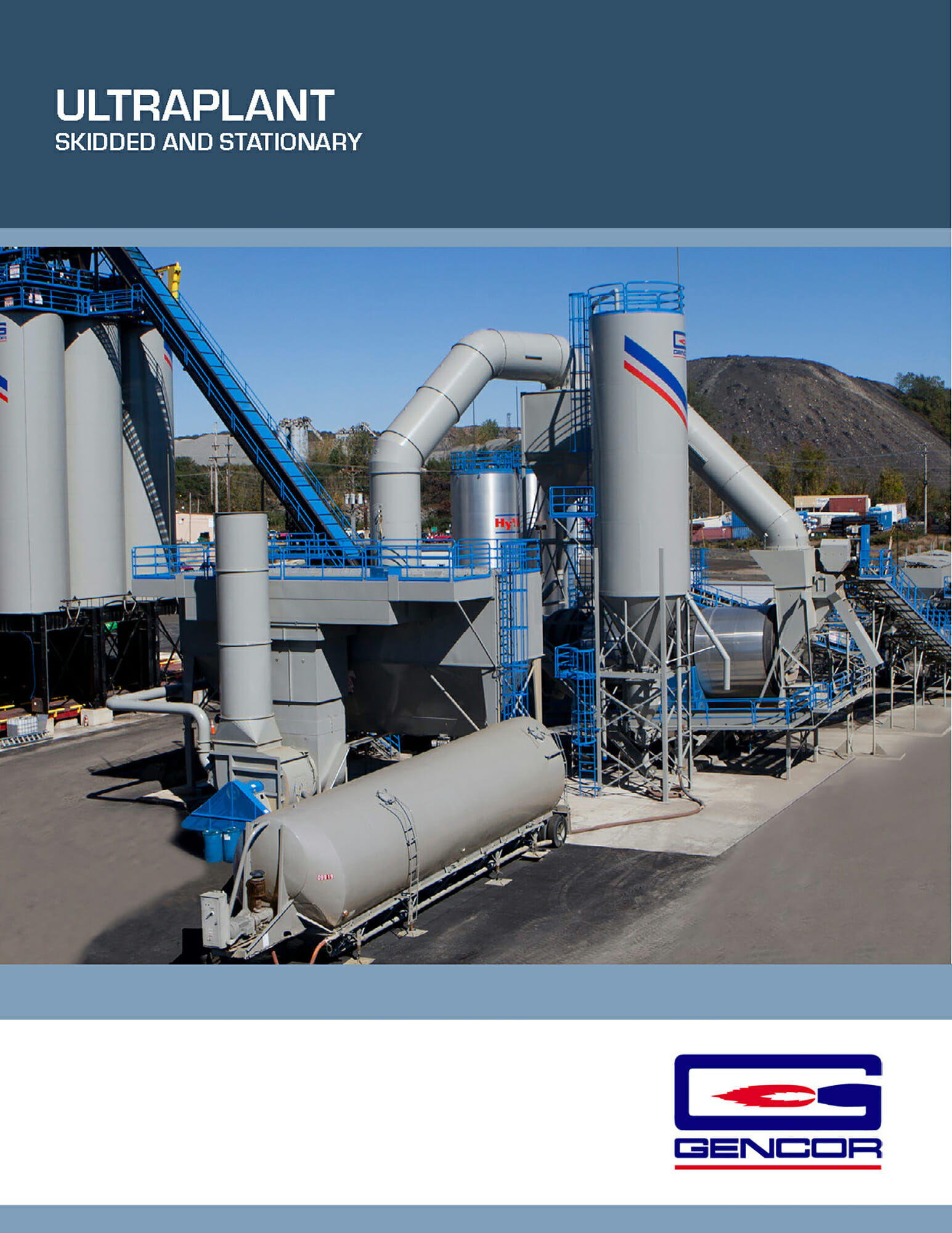

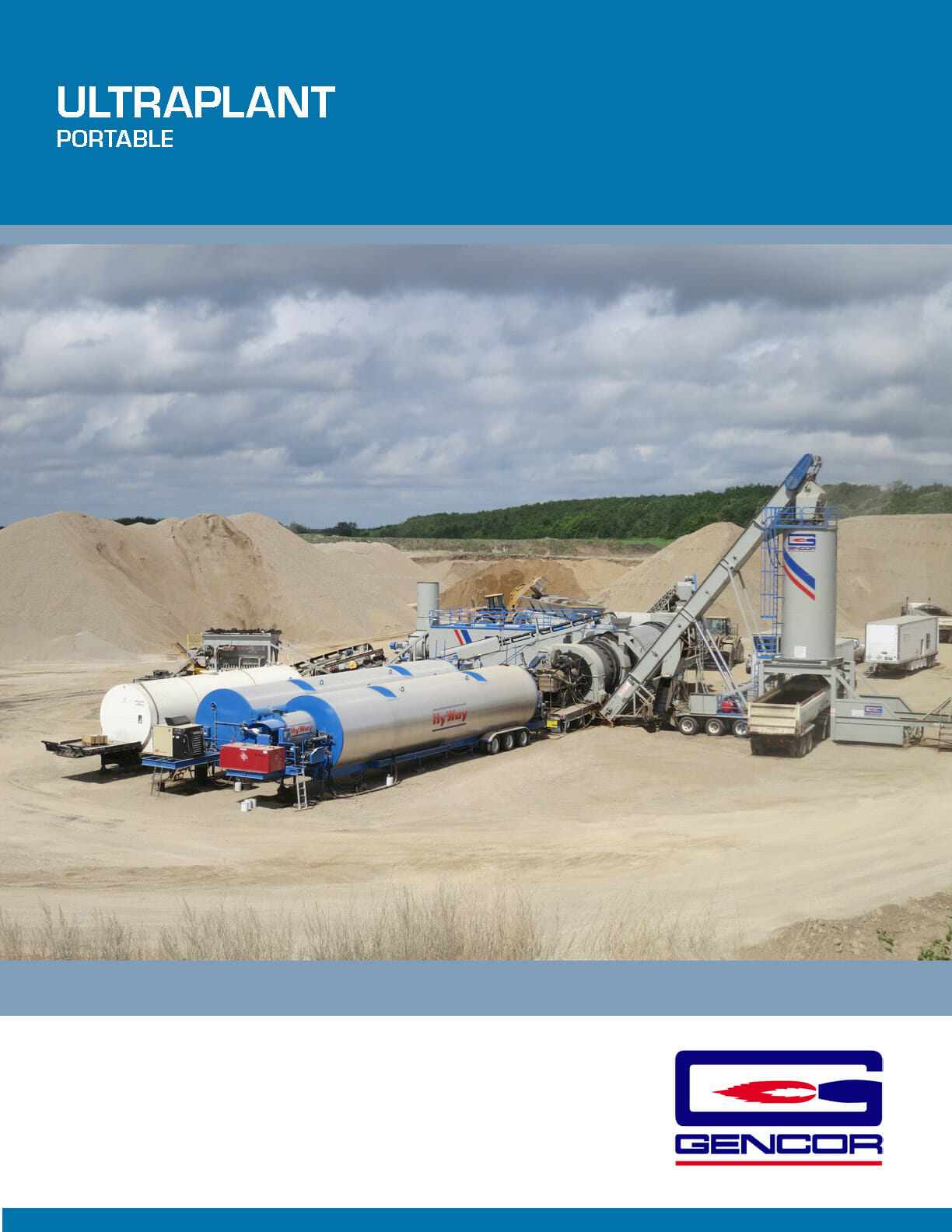

Transfer Conveyors

Gencor offers the most versatile and comprehensive line of transfer and rotary conveyors in the industry. With hundreds of applications to its credit, Gencor has confronted virtually every silo arrangement imaginable for both batch and continuous hot mix plants.

Constructed of the same heavy-duty components of Gencor’s large drag slats, each conveyor is constructed of dual backbone heavy-duty beams with replaceable liners for long life and durability under the most demanding conditions. All drive systems are oversized to ensure continuous flow of material with even the most viscous of polymer asphalts and SMA mixes. The ¾” AR slats are chain driven from the center for maximum torque, and are wear guaranteed for one million tons. An exclusive 4” pitch roller chain provides maximum strength for reduced wear on the rollers and pins.

Features:

- Dual backbone heavy-duty beams

- 4” pitch roller chain

- ¾” AR slats

- 1 million ton guarantee

- 1” Nihard liners

- Floating electric heat