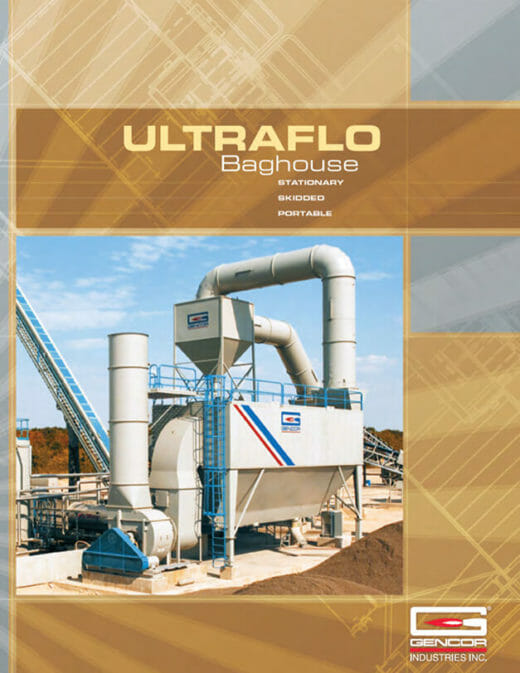

Skidded Ultraflo®

Skidded baghouse designs are shipped in two modular sections for easy field installation.

All bags and cages are completely pre-fitted from the factory, eliminating the need for field bag installation.

All Skidded baghouses include a steel base support structure, eliminating the need for independent concrete footings.

Various independent fines metering and waste systems are available to accommodate any state requirement.

Skidded Features:

- Two-piece modular design

- Fully insulated sidewalls and top

- Bags and Cages installed at factory

- Skid mounted package